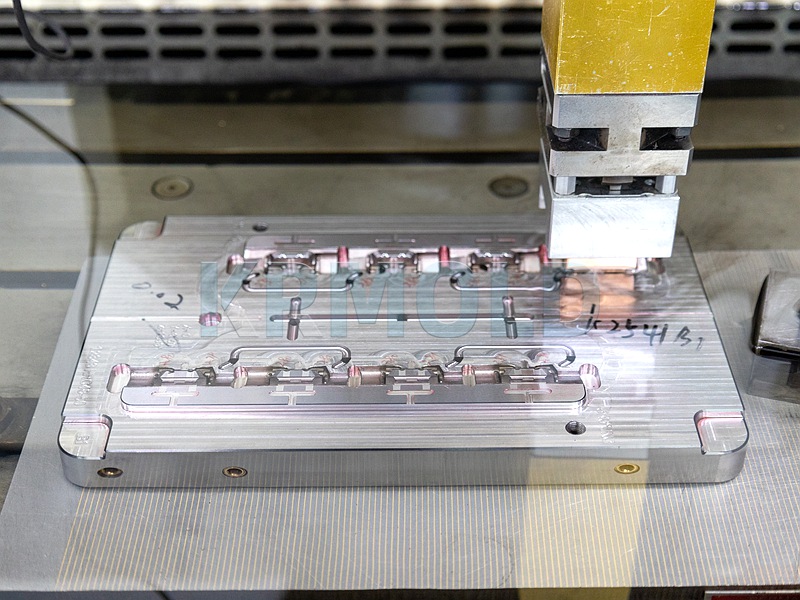

The injection mold EDM (Electro-Discharge Machining) workshop is a processing unit designed for complex cavities, precision textures and microstructures in injection mold manufacturing. Its core is to achieve micron-level precision mold molding by corroding metal materials through electrode discharge.

EDM removes materials through pulse discharge between the electrode and the workpiece. There is no direct physical contact during the processing process, which avoids the mechanical stress caused by traditional cutting. It is particularly suitable for the processing of thin-walled and easily deformed molds.

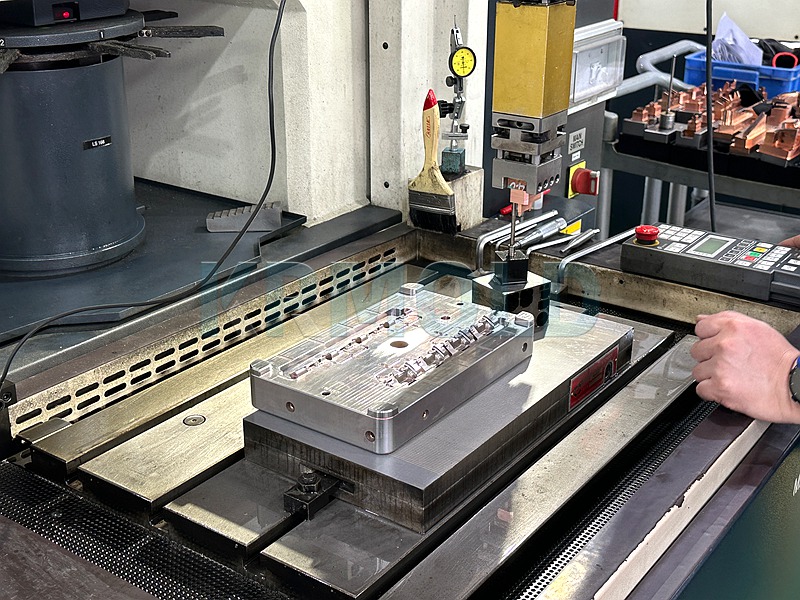

KRMOLD uses Japanese Makino EDGE 3 and Chinese Hanba CNC HE130 EDM precision processing equipment to realize programming and automatic generation of discharge parameters. The operator only needs to clamp the electrode to start the processing. The built-in probe realizes in-situ measurement of the workpiece and reduces repeated clamping errors. It solves the limitations of traditional processing in accuracy, material hardness and complex structure, and is an indispensable core link in precision mold manufacturing.