Automotive Lighting Injection Molds Solution

——

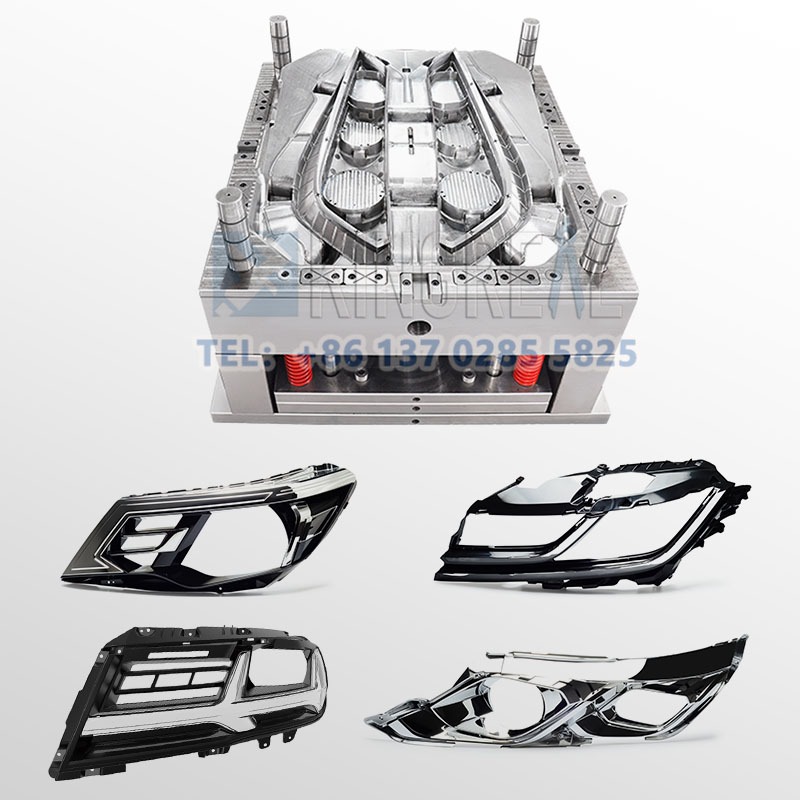

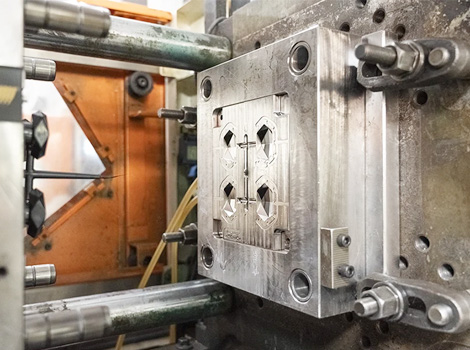

KRMOLD provides customers with complete Automotive Lighting Injection Molds solutions. With complete design and production capabilities, KRMOLD provides automotive lighting companies with high-precision, long-life (up to 30K cycles) injection molds to meet customers' needs for high-volume, high-quality automotive lighting products.

In the field of automotive lighting, Automotive Lighting Injection Molds are used to manufacture plastic parts with complex structures, such as lamp housings, light guide strips, lenses, etc. Since automotive lighting parts require very high optical properties, the injection molds are required to ensure that the product surfaces are smooth and free of bubbles or deformations, and KRMOLD has a professional production and design team to provide customers with KRMOLD has a professional production design team to provide customers with tool design, tool creation and tool iteration standard industry production process, KRMOLD is committed to helping customers to provide a complete production solution, to become a long-term partner!he material shrinkage and cooling rate to avoid light scattering.

Specialized Design And Production Capacity For Injection Mold

——

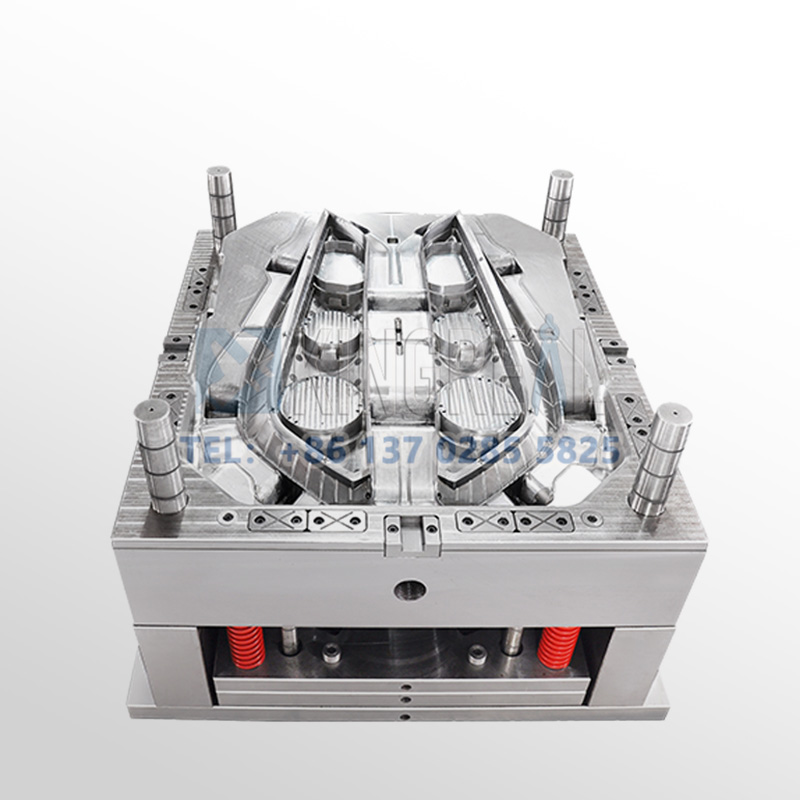

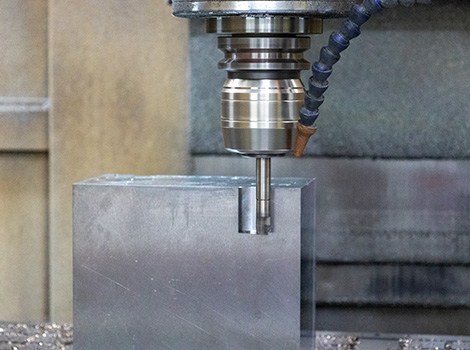

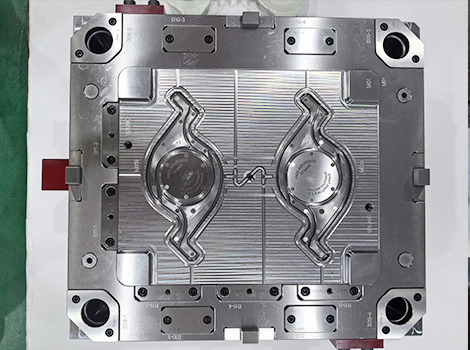

KRMOLD employs Makino V33CNC and EDGE sparking machine in the manufacture of Automotive Lighting Injection Molds, realizing integral machining of the mold core (reducing the number of splices and batch fronts), and the surface roughness of the cavity reaches Ra0.02μm or less. The deep hole drilling technology realizes the cooling channel close to the mold surface, which shortens the molding cycle time by 15%.

KRMOLD also has a perfect manufacturing quality control system for Automotive Lighting Injection Molds, applying three-dimensional measuring system (Hexagon) to check the accuracy of the molds to ensure that the dimensional tolerance is ≤±0.005mm, and at the same time, KRMOLD's injection mold products have passed the ISO 9001 and IATF 16949 quality inspection, and the standardized process documentation from design to delivery has been established. standardized process documentation from design to delivery, and take a collaborative approach with each customer to ensure that each project achieves the desired results.

Automotive Lighting Injection Mold Technical Feature

——

Automotive lighting injection molds produce finished parts with dimensional accuracy of ± 0.3% - ± 0.5%, surface roughness (Ra) can be controlled at 0.8-1.6μm, and the density is close to the theoretical value of more than 95%. This is crucial for precision parts in automotive lighting (such as sensor housings or fixing parts), which can reduce subsequent processing costs and improve reliability.

KRMOLD injection mold manufacturing can be applied to stainless steel, titanium alloys and so on. For example, the lightweight nature of titanium alloys (only 60% of the density of steel) optimizes the weight of a headlight bracket or housing while maintaining high strength. In addition, the high heat resistance of tungsten alloys may be used for lighting components that require high temperature resistance (e.g., LED heat sink modules).

KRMOLD designs automotive lighting injection molds suitable for mass production, with a single mold life of up to 300,000 cycles and a material utilization rate of nearly 100%. In the automotive lighting industry, this can significantly reduce the manufacturing costs of standardized components such as metal clips and fixing bolts.

Specification Of Automotive Lighting Injection Mold

——

| Mould Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

| Mold Standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

| Mold Cavity | Single/Multi |

| Maximum Mold Size | 1500*1500 mm |

| Mold Material | H13,2190 VAR,Resin,Plastic |

| Plastic Material | PP, PC, PS, PE, PET, POM, PA,PU, PVC, ABS,PMMA etc. |

| Mold Life | 30K |

| Surface Treatment | Polish,texture,painting,screen printing,turnkey project |

Common Injection Molding Processes

——

“Automotive Lighting Injection Mold involves different types of injection molding processes to meet a variety of customized production needs of customers.”

Rotational or rotary molding to ensure precise alignment of the cavities between the two injections, used for compounding hard structures (PC/ABS) with elastomeric seals (TPE), e.g. for the production of lampshades such as clear and frosted.

Gas-Assisted Injection Molding

The Gas-Assisted Injection Molding process produces hollow structures, such as automotive light housing reinforcements or hidden airway designs, which eliminate shrink marks and improve surface flatness. The process utilizes high-pressure gas to drive the melt to completely fill the cavity and create a hollow structure inside the part, while reducing shrinkage and deformation through gas pressure retention.

Application Of Car Head Light Plastic Injection Mold

——

“Automotive Lighting Injection Molds are used in several key areas of vehicle lighting systems.”

Major Exterior Lamp Assemblies

1. Headlights (headlamps)

Headlamp injection molds are used to manufacture the core components of vehicle headlamps, including lenses, decorative frames, housings and reflectors.

2. Tail light

Tail lamp molds need to take into account both functionality and decoration, such as through 3D printing technology to achieve complex curved surface modeling, to meet the needs of personalization.

Other Exterior Lamps

Fog lamps, turn signals, daytime running lights

The molds for these lamps need to be adapted to the installation space and shape requirements of different models.

Interior Lighting & Function Lamps

Interior ambient lighting, instrument panel back-lighting

Injection molds for manufacturing light guides, lampshades, and other components with uniform light distribution through highly translucent materials (e.g., PMMA) and precise texturing.

FAQ:How to get a quote for custom injection molds?

——

1. Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing)

2. Provide 2D or 3D plastic part drawings should be provided.

3. Provide the production volume, appearance requirements, tolerance standards, etc.

Especifique o tipo de plástico (por exemplo, PP, ABS) e os requisitos de pós-processamento (por exemplo, pulverização, serigrafia) e forneça desenhos de peças plásticas 2D ou 3D. Ao mesmo tempo, forneça o volume de produção, requisitos de aparência, padrões de tolerância, etc.

Em termos gerais, nossos engenheiros começarão a preparar a cotação imediatamente após o cliente fornecer os requisitos completos de produção. Geralmente, leva cerca de 1-3 dias.

O prazo de entrega para moldes de injeção regulares é geralmente de 30 a 60 dias, e pode ser maior para moldes complexos. Por exemplo, o prazo de entrega típico para moldes de silicone líquido é de cerca de 60 dias, cobrindo design, fabricação, teste de molde, etc.

Tecnologia de processamento de alta precisão: Equipamentos de alta precisão, como centros de usinagem CNC (CNC) e usinagem por eletroerosão (EDM), são usados para otimizar o processo de design em combinação com software CAD/CAM. Controle de qualidade: Inspeção das principais dimensões do molde pela Máquina de Medição por Coordenadas (CMM) e verificação de múltiplos lotes de amostras durante o estágio de moldagem de teste. Seleção de material: use aço para matriz com alta resistência ao desgaste (por exemplo, H13, S136) e tratamento de superfície (por exemplo, nitretação, cromagem) para porcas de matriz para prolongar a vida útil.

Após cada 50.000 moldes, verifique o pilar guia, o pino ejetor e outras peças de desgaste, e limpe o plástico residual e a ferrugem na superfície do molde. Use graxa de alta temperatura para peças deslizantes (por exemplo, parte superior inclinada, controle deslizante) para reduzir a perda de fricção. Certifique-se de que o circuito de água esteja suave e a diferença de temperatura seja ≤5℃ para evitar rachaduras no molde devido ao estresse térmico.

O custo do molde dos materiais foi responsável por cerca de 30-40% (como 1 tonelada de preço de aço P20 de cerca de 20.000 yuans), os custos de processamento foram responsáveis por mais de 50% (taxa horária de trabalho CNC de cerca de 80-150 yuans / hora). A produção em pequenos lotes pode escolher o molde de alumínio ou simplificar o design estrutural; mais de 100.000 peças são recomendadas para usar insertos de carboneto para aumentar a vida útil!

Os produtos de injeção de molde precisam atender totalmente aos requisitos de design (como tamanho, aparência) e podem ser de produção contínua e estável. A marcação do molde, os relatórios de inspeção (como teste de dureza do material) e os desenhos de engenharia devem ser completos.

O aço do molde (como S136H, NAK80 e outros materiais importados custam mais) e o tipo de embrião do molde (o custo de curto prazo do molde de alumínio é baixo, mas a vida útil é curta) afetam diretamente o custo. O uso da tecnologia de design CAD/CAE/CAM, sistema de canal quente, etc. aumentará o investimento inicial, mas pode aumentar os benefícios de longo prazo (como reduzir os sprues e aumentar a capacidade de produção).